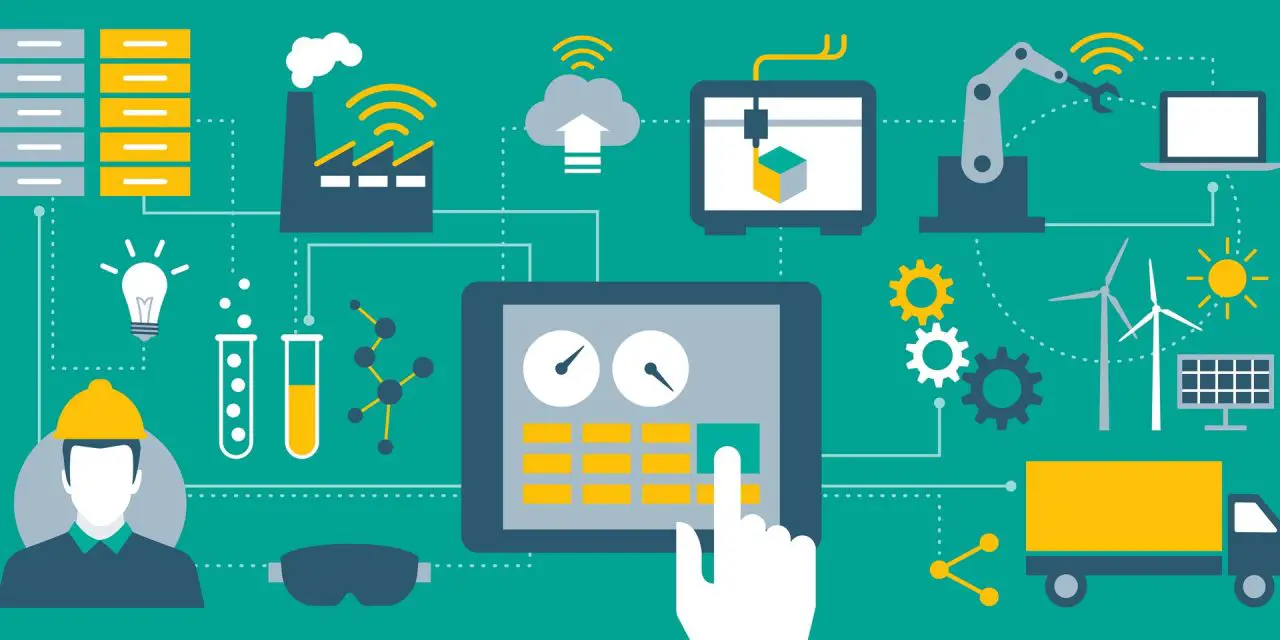

The Internet of Things has brought about numerous benefits due to the high efficiency it brings to companies and organizations. This article explains the uses of IoT, as well as the advantages brought about by IoT in supply chain management.

Before we explore the various uses of IoT in supply chain management, let us define the term IoT.

Table of Contents

What is IoT?

The Internet of things is a system of interrelated computing devices, mechanical and digital machines provided with unique identifiers and the ability to transfer data over a network without requiring human-to-human or human-to-computer interaction.

The IoT is able to use sensors to measure various parameters which help improve the supply chain management process. The parameters measured include, but are not restricted to the following: location, light levels, speed of movement as well as the humidity. For example temperature sensors can measure the temperature of the environment in which perishable goods are in, and notify the customer if the products are going bad.

Advantages of IoT in Supply Chain Management

1. Location

The IoT devices in the supply chain are able to detect the exact location of the goods. This is achieved through technologies such GPS technology. This provides reassurance to both the client and the manufacturer as both of them will be able to see the location of their goods in real time.

In addition, tracking of goods in storage will be made quite easy. Products can be given IoT devices such as GPS and RFID tags in order to locate their precise location within the warehouse. This will reduce the amount of time taken to locate the goods within the ware house.

2. Efficiency

The supply chain IoT devices allow for efficient storage and distribution of products. This efficiency is achieved as the workers will spend less time locating goods within the warehouse. In addition, through the use of cloud computing, the manufacturer is able to know exactly where there is a demand in his goods, and through demand forecasting, he can prepare to scale up, or scale down production.

3. Monitoring

Supply chain IoT devices make it quite easy to monitor the storage conditions of the products. Some products such as chemicals, and perishable food need to be stored in ideal conditions. Supply chain IoT devices which measure environmental parameters such as the light intensity, humidity, temperature and pH can be used to monitor the state of the products. If the products are seen to begin to degrade in quality, the manufacturer can immediately carry out preventative actions, thus, resulting in him or her avoiding potential losses. In addition, the exact point at which the product degradation began would be identified, and the process e.g. manufacturing or transportation process could then be improved.

4. Movement Tracking

Another benefit of IoT in supply chain management is the ability to track the movement of the various product. The IoT devices make it easy to predict how the goods will move through the supply chain. This is achieved by supply chain management IoT devices that track the traffic flow of the products. This makes it easier for the distribution centres to prepare to receive goods from the manufacturer. This therefore reduces handling times and also ensures the efficient processing of materials. In addition, this helps to foster inventory visibility as the supply chain IoT devices will show the exact products’ location in real time.

Application of IoT in Supply Chain Management

1. Transport Management

Transportation is a key priority in supply chain management. Up to 83% of supply chain managers list this as a top priority. Before the advent of the Internet of Things, companies would use what they called the “Just in time” strategy because it was seen to be cheaper than having to take the stock and store it. This was done to minimize ware house space requirements. Due to the advent of IoT in supply chains, the logistic process has been made cheaper by offering the real time demand to hold the stock, as well as the option to define the frequency to reorder the goods. This minimizes warehouse space requirements as well as transportation costs.

2. Inventory Management

This is quite a tedious process. Companies have to track the inventory that is about to expire, the inventory that is in transit, the inventory currently in stock, as well as the stock of raw goods. This is quite a challenge, and this is made simply by the integration of IoT in the supply chain. This allows the implementation of real time inventory management capabilities as well as the zero inventory strategy. Supply chain management IoT also helps businesses in optimising capital investment in inventory. It allows the businesses to implement the economic ordering quantity model or build to stock or make to stock models much more adequately and efficiently.

3. Delivery Management

This plays a crucial role in supply chain management. This is because white clove service, pre schedule deliveries, last mile deliveries as well as freight claim processing need much more attention. The need to have more personalized product delivery services continues to increase and this is where IoT in supply chain management comes in. It optimizes the transportation routes, improves the real time asset tracking, and increases the operation visibility. In addition, it results in efficient last mile delivery, and complete and on time delivery operations are more effectively carried out. IoT works so much that companies such as DHL plan on implementing IoT and block chain based track and trace models across geographies in order to increase the delivery accuracy, reduce delivery errors, and provide end to end live support. It also improves the data transparency.

4. Monitoring

The entire supply chain makes use of supply chain IoT devices. The producers, such as farmers can use IoT devices to monitor the parameters such as the soil moisture and temperature and use this to decide the best time to plant and harvest. Manufacturers can use IoT enabled cameras to spot defects and reject faulty goods. Food retailers can monitor the temperature as well as the humidity of goods in storage in able to make sure that the goods reach the stores in the best condition possible.

Conclusion

This article has explored the various advantages associated with supply chain management IoT. The various applications of IoT in supply chain management were also given.

We hope you enjoyed this article!