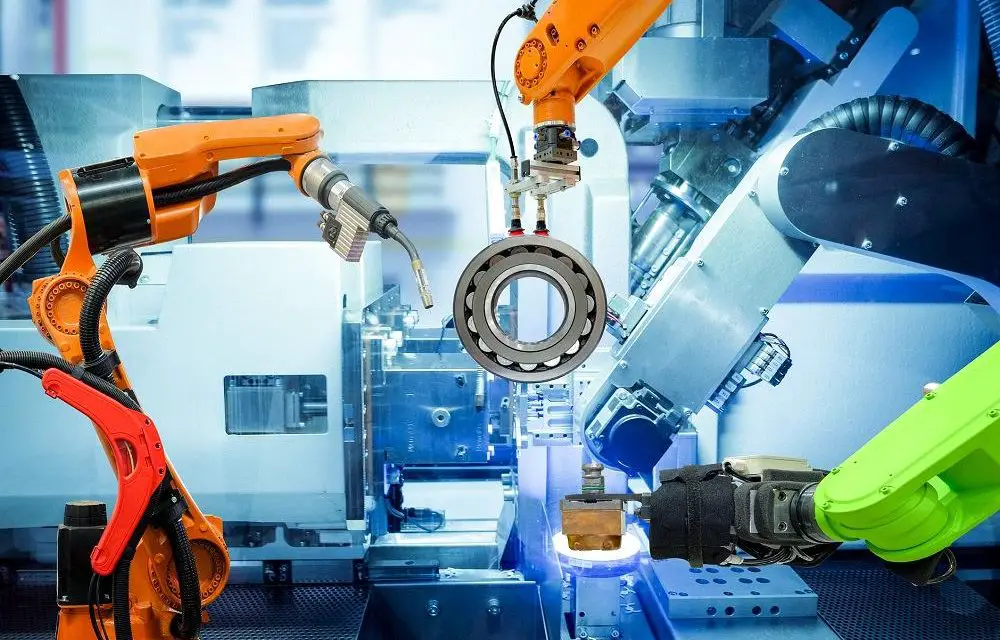

The advent of the 4th Industrial revolution, and the rise of the smart factory has resulted in a monumental shift in the processes present in manufacturing industries. This has been made possible by technologies such as cloud computing, Artificial Intelligence (AI), and Machine Learning (ML). This article investigates the use of IoT in manufacturing.

Before we explain the various applications of IoT in manufacturing, let us define a key term, Manufacturing IoT

Table of Contents

What is Manufacturing IoT?

Manufacturing IoT is the use of network-connected sensors and other monitoring devices used to improve the manufacturing and quality of an organization’s products and product parts.

IoT has been the force behind the improvement of production processes in various industries such as manufacturing, retail as well as logistics. The manufacturing sector has benefited quite heavily from manufacturing IoT as it results in a more efficient production process, less down time and cost savings to the manufacturing industries. This is achieved through facilitating the production flow in a manufacturing plant by automatically monitoring the development cycles, performing inventory management and managing the warehouses present.

Now that we have an appreciation of IoT in manufacturing, let us investigate the driving forces that led to the adoption of IoT in manufacturing.

Driving Forces behind Manufacturing IoT

1. Safety

Manufacturing IoT greatly improves the safety of the workers present in the manufacturing industry. This is achieved through the use of wearable IoT that is able to monitor the health state of the workers, and allow the supervisors to take preventative actions before it is too late. In addition, manufacturing IoT is able to identify potential hazards and immediately notify the engineers present. An example is the use of manufacturing IoT to detect and monitor gas pipes. If any leakages are detected, then the relevant actions are taken. If the gas is poisonous to humans, then they are immediately vacated from the area.

2. Cost Reduction

Manufacturing IoT brings a host of benefits. These include smart inventory management in which various IoT devices such as RFID and GPS tags are used to track the amount of inventory present as well as the location of the products. This results in lower search times, and with facilities provided by manufacturing IoT such as notification to supervisors when a stock shortage is imminent and automatic ordering of new stock, this results in more agile operations being carried out which reduce machine downtime. As a result, operational costs are greatly reduced.

3. Time to Market

Nowadays we live in an instant culture. Instant messaging, instant communications, and instant purchasing. The consumer wants the products he or she wants to arrive to his or her doorstep as quickly as possible. Through the use of IoT in manufacturing, this is made possible as the manufacturing and supply chain operations are now more efficient and faster, resulting in a reduction in product cycle time. A company that provided an astonishing reduction in time to market is the motorcycle giant, Harley-Davidson. This company reconfigured its York, PA manufacturing facility and reduced the time needed to manufacture a motorcycle from 21 days to an astonishing 6 hours.

Examples of IoT Driven Manufacturing Operations

1. Equipment Monitoring

The use of manufacturing IoT in monitoring machine utilization can result in a boost of manufacturing productivity by anything from 10 – 25% according to a study by ITIF. This translates to up to $1.8 trillion in global economic value by 2025. The monitoring starts by obtaining relevant data provided by the sensors in the machine. This data includes the product output, run time, actual operating speed, etc. This data obtained is then gathered in real time and sent to the cloud for processing. The cloud then aggregates the data, performs analysis and then translates it into useful information. This information is then visualized and displayed to the workers through the use of an application. The information displayed gives valuable information such as the machines’ cycle times, the downtime, as well as the number of parts produced.

2. Quality Monitoring

Manufacturing IoT enhances the quality management process. The traditional method of monitoring the quality of produced goods uses the inspecting of the work in progress. This approach is applicable only for discrete manufacturing, its labour intensive and costly, and since it is rarely possible to inspect every work in progress this method provides only a fractional view.

The new manufacturing IoT based process involves monitoring the condition and calibration of the machines. This helps to detect bottlenecks in the manufacturing process, and through this, underperforming machines and improperly tuned machines can be detected. In addition, readings from the sensors in the machines can be used to identify potential product defects, and the source of the problem can be quickly identified.

3. Safety

It is impossible to mention the manufacturing process without mentioning the aspect of safety. Safety is the most important aspect of the manufacturing process that companies pour in a lot of money to meet the strict safety standards present. Through the use of manufacturing IoT, worker safety can be greatly improved. This can be achieved through wearable sensors. These sensors gather information such as skin temperature, their heart rate, their location as well as the humidity present. This information is sent to the cloud for analysis, and if any unusual behaviour patterns are detected e.g. unusual heart rates and sudden vertical movements, preventative actions can be immediately carried out.

4. Predictive Maintenance

IoT in manufacturing enables predictive maintenance solutions to be carried out. This allows the manufacturer to reduce the equipment maintenance costs. The machinery will have sensors which collect a wide variety of data such as the temperature, vibration frequency, pressure, etc. This data is then transmitted to the cloud for processing. The data is analysed and factors such as the usage history, maintenance data and the age of the equipment is used to determine the health of the machine. Once the potential failure of one or more of the parts of the machine is detected, the supervisor is notified, and spare parts can be immediately ordered to address the potential problem.

Conclusion

This article has given the definition of manufacturing IoT as well as the driving forces behind IoT in manufacturing. Examples of IoT driven operations were then given.

We hope you enjoyed the article.