Temperature is one of the most important physical quantities measured in industries. This is because most physical, biological, chemical, mechanical and even electronic systems are affected by it. This article explains on the types of temperature sensors used to measure this very important physical quantity.

Table of Contents

What is a Temperature Sensor?

Note: When reading literature pertaining to the subject of temperature, it is common for one to come across the term absolute zero. This is simply zero kelvins (0 K) i.e. – 273 0C

Basic Temperature Sensor Categories

1. Contact Sensors

These types of temperature sensors need direct physical contact with the media or object whose temperature is to be measured. These can be used for solids, liquids as well as gases over a wide range of temperatures.

Examples are: Bourdon gauge thermometer, mercury thermometer, alcohol thermometer, thermocouples, and resistance temperature detectors.

2. Non-Contact Sensors

This temperature sensor type does not need any physical contact with the media or object that is being sensed. These can be used for non-reflective solids and liquids but are not useful for gases due to natural transparency. They use Plank’s law to measure temperature.

Examples are: non-contact infrared thermometers, thermal scanners, radiation thermometers, optical pyrometers, fibre optic temperature sensors

Types of Temperature Sensors

1. Thermocouple

This is a type of temperature sensor that is constructed by joining two dissimilar metals at one end. This end is referred to as the hot junction. The other end of the dissimilar metals is known as the cold junction. If there is a difference in temperature between the hot junction and the cold junction, a small voltage is produced. This voltage is what is referred to as the electromotive force and can be measured and used to indicate the temperature present.

2. Resistance Temperature Detector

This type of temperature sensor has a resistance that changes with temperature. It is usually built from platinum. There are Resistance Temperature Detectors (RTDs) that are made from nickel or copper. RTDs exhibit a fairly linear resistance to temperature curves over their operating regions and any non-linearity is highly predictable and repeatable.

3. Thermistors

This is a temperature sensor type whose resistance changes with temperature, much like the RTD. These are, however, made from semiconductor materials. These devices have a highly non-linear resistance vs. temperature curve. This makes them quite suitable for applications that need a highly sensitive temperature sensor type as a very small temperature change can result in a large resistance change.

4. Semiconductor Sensors

This is a type of temperature sensor with very many classifications. Examples include diode temperature sensors, resistance output silicon, current output, digital output, voltage output. These types of temperature sensors give quite a high accuracy and a high linearity over the operating range 55-150+ 0C.

Circuits can be added to amplify the output to convenient values such as 10mV/0C. This means for every increase in 10mV, the output temperature will increase by 1 0C. These are suitable for cold junction compensation circuits for a wide temperature range of thermocouples.

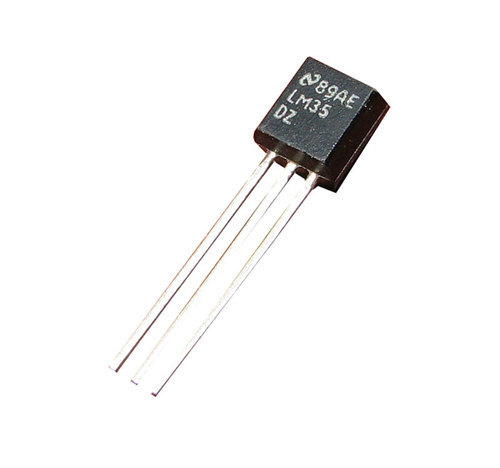

An example of the semiconductor sensors is the LM35.

The LM35 is a small integrated circuit semiconductor sensor. It is mounted on a Printed Circuit Board (PCB). It provides a digital output, and is popular due to its high accuracy and high linearity over the temperature range 55-1550C. In addition, it is quite easy to interface with microcontrollers or microprocessors.

Application of various types of temperature sensors

- In electric motors to measure the motor winding, bearing temperature, internal housing temperature, external body temperature, and temperature of the brushes. This therefore reduces downtime in industries, and it saves the company from potential losses because the costs of replacing a motor, or one of its components is quite high.

- These sensors are used in rubber and plastic industries in the production line to monitor the production of the end products. This is an important application, as it results in the end products adhering to a pre-set quality standard.

- For monitoring in power stations. Power stations contain machines that are highly sensitive to temperature. For example, transformers need to operate in a certain temperature range. Above the maximum temperature, the insulating medium, oil may disintegrate and cause a fire, thus, damaging equipment and plunging the nation into darkness.

- In humidity and air conditioning. Server rooms contain computers that process incredible amounts of information. As a result, they dissipate a lot of heat. There is a need to keep these devices in an area that is well regulated to keep them functioning at their optimum performance.

- In heating control systems. Buildings need central heating. Temperature sensors are mounted in convenient places in the building. They measure the air temperature that is present. The signal is then sent to the main processing unit, and it checks if the temperature present is higher or lower than the current temperature. It then takes relevant actions such as turning the heaters on or turning the heaters off.

- In mechanical engines. In this scenario, temperature sensors are needed to measure the engine oil temperature and the engine bearing temperature. This will prevent the mechanical engine from overheating.

- In electric cables to measure the internal resistance of the cable. In this scenario, they are used in the form of a heat shrink tube or metal housing. This saves the electric cables from burning due to overheating.

Conclusion

This article’s main purpose was to give the basics of temperature sensors. It explained the types of temperature sensors, and gave applications of the various temperature sensor types.

I hope you enjoyed the article.