The Internet of Things has brought a host of benefits to industries such as manufacturing. It makes the process quicker, more efficient and use less resources. This article will explain on the industrial IoT applications.

Before we get into details about industrial IoT applications, let us first define the term industrial IoT.

Table of Contents

What is Industrial IoT?

Industrial IoT can be defined as the application of instrumentation, connected sensors, and other devices to machinery and processes in industrial settings. This allows for data collection from the sensors. This data is then analysed on a cloud platform using algorithms such as Machine Learning. This data can then be accessed on site, or remotely.

Providing remote access to the data as well as the data analytics will help the process of continuous improvement. In addition, there will be the availability of support from a device expert or process expert, and thus, resolve unwanted situations quickly resulting in lower downtime. Combining the remote access with new technologies will allow for better diagnostics, earlier detection of faults, and as a result there will be faster service. It also allows for better planning and an increase in efficiency.

Benefits of IoT

1. Production Visibility

Industrial IoT allows for sensors, machines and tools that are present on the production floor to be connected to each other. This gives the personnel such as the process engineers as well as the managers the much needed visibility into the production process. By connecting with the tools that are used by the production floor workers, the supervisors as well as the plant managers are able to get a real time view of the yield of their teams. This allows the supervisors to identify any bottlenecks as well as to find the root cause of any problems that may be present. This allows the team to perform work at a much faster rate.

2. Faster Improvement Cycles

Industrial IoT provides a host of benefits to everyone. The quality engineers, process engineers and other engineers benefit. In traditional, non-IoT bases systems, the engineers on the shop floor need to manually collect, aggregate and analyse the data. An IoT enabled shop floor gives the engineers the ability to automate the data collection process. This leaves them with more time to actually improve the process.

3. Higher Operator Productivity

Industrial IoT can increase the productivity of the manufacturing workforce. The operators can use IoT enabled tools such as torque drivers. These automatically adjust the settings of the tool to suit the operation that the operator should be doing. This speeds up work. In addition, pick to light devices can be used to help operators find the piece they need quickly, and thus, reduce their cycle time.

4. Supply Chain Optimization

Industrial IoT can be used to monitor events across a supply chain. It provides access to real time information. This is achieved by tracking the inputs, the equipment as well as the products.

Applications of Industrial IoT

1. Factory of the Future

In this application of Industrial IoT, the aeroplane manufacturing giant Airbus has launched a digital manufacturing initiative in order to streamline operations and to bolster production capacity. The tools have sensors integrated into them, as well as the machines. The workers use wearable technology. This technology includes smart glasses which are designed to increase safety and reduce errors.

2. Tool Tracking

In this application of Industrial IoT, Bosch identified that its workers spent a great deal of time just looking for their tools. The company decided to add sensors to the tools in order to make the tracking process much quicker and easier.

3. Augmented Reality (AR)

In this application of Industrial IoT, Caterpillar introduced the concept of educating the frontline workers using AR. An example is if an air filter in the machinery needs to be replaced, the company can send basic instructions to the frontline worker on how to replace the filter via an AR application.

4. Minimizing Downtime

In this Industrial IoT application, Fanuc reduces downtime in its industrial facilities. It uses sensors in its robotics together with cloud based analytics. This allows the company to predict when the failure of a component such as process equipment or a robot is imminent. This allows the company to greatly reduce costs as downtime is rather expensive.

5. Monitoring

In this Industrial IoT application, Komatsu deployed connected technology in its production facilities based in Japan. Komatsu linked all the robots at its central production facilities to the internet. This allows the managers to be able to monitor the operations in real time.

6. Increase in Outputs

In this Industrial IoT application, the Oil giant Shell designed and developed “smart oil fields” Through the use of advanced technology, this company is able to obtain 10% more oil and 5% more gas than traditional fields. In addition, the company links its high technology wells with a fibre optic cable that allows remote employees to monitor the operations remotely.

7. Safety

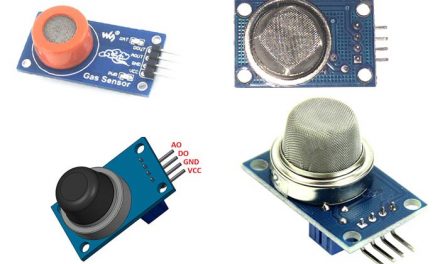

In this application of Industrial IoT, North Star BlueScope Steel employed the use of wearable technology. The employees have wearable technology in their helmets and wrist bands. This allows the managers to track the safety of their employees. In addition, the managers can also spot hazardous conditions before they lead to injuries. The wearable IoT devices track important information such as the pulse, body temperature, and activity level. This allows the supervisors to give the workers a break when necessary. In addition, the connected sensors present monitor extremes in environmental temperature and they also detect the presence of toxic gasses and radiation.

8. Tracking

In this Industrial IoT application, the shipping giant Maersk uses IoT devices to keep track of its assets as well as to optimize fuel consumption and the routes of its ships. This technology has been quite beneficial as the company ships refrigerated containers. The contents of such containers could easily go bad in the absence of tight temperature control.

Conclusion

This article defined the term industrial IoT. The benefits associated with industrial IoT were given as well as the applications of industrial IoT. We hope you enjoyed the article!