Electronic systems were designed to mimic the human being. They have a Central Processing Unit which mimics the brain, cameras which copy the eyes, and gas sensors which mimic the nose. In this article, we will find out more about the types of gas sensors, as well as the applications of various gas sensor types.

Table of Contents

So what is a Gas sensor?

A gas sensor is an electronic device that is designed to detect the presence, or concentration of gases in the atmosphere. Based on the concentration of the gas present, the resistance of the material inside the sensor changes and the output voltage value is then used to determine the type of gas present as well as its concentration.

These devices are used to detect various types of gases. The gases they detect include flammable, combustible and oxygen depletion. The gas sensors are widely used in the heavy industry.

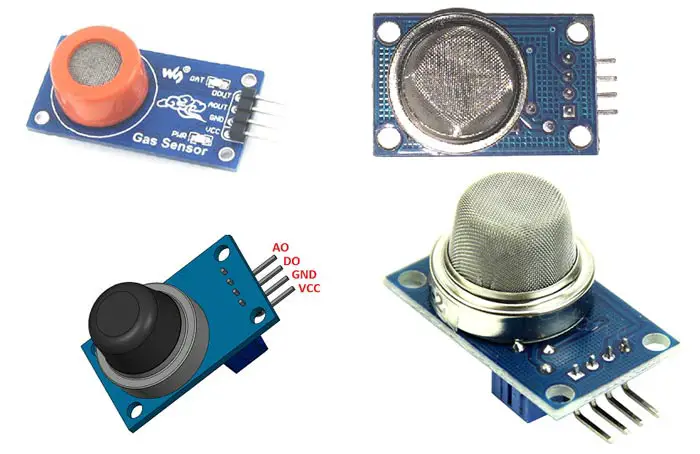

The type of gas the sensor is able to detect depends on the sensing material present in the sensor. These sensors are usually available as modules which contain the sensor as well as a circuit with components such as integrated circuits. In gas sensors, the integrated circuits are usually comparators. These can be set for a particular threshold value of the concentration of gas. When the gas exceeds this threshold value, then the digital output pin goes high. They usually also have an analogue pin which is used to measure the exact concentration of the gas present.

Types of Gas Sensors

Gas sensors are classified based on the sensing element used to build it. Below is the classification of various types of gas sensors based on the sensing element present:

1. Acoustic based gas sensor

These types of gas sensors detect the acoustic emission that is created when a pressurised gas expands in a low pressure area through a small opening. The acoustic sensors detect the changes in the background noise of the environment. This is based on the premise that most high pressure gas leaks generate wound in the ultrasonic range of 25kHz to 10MHz. The sensors are therefore able to easily distinguish these frequencies from background acoustic noise that occurs in the audible range.

2. Metal Oxide based gas sensor

These gas sensor types use a heated ceramic bead which acts as a variable resister. The resistance usually drops in the presence of gases that can be oxidised.

3. Electrochemical gas sensor

In this type of gas sensors, a battery is present in which a gas is required to complete the chemical reaction and produce a small current. These may or may not be heated depending on the type. These are usually made to have a limited life when they are manufactured.

4. Catalytic

These gas sensor types have two heated elements. One element catalyses oxidation of gases and the other does not catalyse the oxidation of gases and acts as a reference electrode. The voltage difference between the active and passive elements is proportional to the concentration of all combustible gases and vapours present.

These sensors are commonly used to measure the combustible gases that present an explosion hazard. This occurs when the concentration of these gases are between the lower explosion limit and the upper explosion limit.

Note: In the list typed above, the most commonly used gas sensor is the metal oxide semiconductor based gas sensor

Design and construction of the various gas sensor types

All gas sensor types have the basic parts that are shown below:

1. Gas sensing layer

This is the main component of the gas sensor. It is used to sense the variation in the concentration of the gases and produce a relevant change in electrical resistance.

2. Heater coil

The purpose of the heater coil is to burn in the sensing element in order to increase the efficiency as well as the sensitivity of the gas sensor. This is made of Nickel-Chromium because it has a high melting point. This enables the gas sensor to stay heated up without getting melted.

3. Electrode line

The sensing element produces a very small current when the gas is detected. It is of great importance to maintain the efficiency of carrying those small currents. As a result, platinum wires are used because it is a very good conductor of electricity.

4. Tubular ceramic

This has a high melting point and is present to help in maintaining the preheating of the sensing layer which gives the sensing layer a high sensitivity. As a result, there is efficient output current.

5. Mesh over the sensing element

This is present in order to protect the sensing elements and the setup from damage. It is also present to prevent dust particles from entering into the mesh and causing damage to the gas sensing layer.

How the gas sensor works

The gas sensor’s ability to detect gases greatly depends on the component present called the chemiresister. The most commonly used chemiresistor is Tin Dioxide. The atmosphere usually has more oxygen than combustible gases. When the sensor is placed in a toxic, or an environment with combustible gases, a chemical reaction occurs, and this reaction results in the flow of current, thus alerting the rest of the system that unfavourable conditions are present.

Applications of Gas sensors

1. Breath analysers

In industries, workers need to be conscious of their surroundings as they can easily get injured. It is important to ensure that the workers are not under the influence of alcohol. As a result, these sensors are important as they are used in breathalysers

2. Gas leak detection

In this application, the various types of gas sensors can be used to detect a possible gas leak. They then sound an alarm to the operators in the area where the leak has occurred, allowing them to leave. They can also give a signal to the system to automatically shut down.

3. Fire Detection

In this application, the various types of gas sensors can be used to monitor the environment. If smoke is detected, an alarm is sounded and workers are given a chance to evacuate the building.

4. Monitor Carbon Dioxide levels

In this application, the various types of gas sensors can be used to monitor the Carbon Dioxide levels in a machine. An example is in a power station. To protect the generator from damage that may result from a fire, carbon dioxide is used. If carbon dioxide is released, then the operators would hear an alarm and immediately vacate the area.

Summary

This article gave explanations of exactly what the gas sensor is. The design and construction of the various types of gas sensors were explored as well as the applications of the gas sensor.

We hope you learnt something new.